Contatti:

+39 0536 284111

Indirizzo:

Via Giovanna Maria Dallari, 2 - 41049 Sassuolo (MO) Italy

In the stationery sector, September is not just any month: it marks the start of a race against time. With the return to school, demand for items such as notebooks, pens, pencil cases, and backpacks grows exponentially in a matter of weeks. This time of year is a critical moment for logistics: flows multiply, deadlines shorten, and accuracy becomes essential.

Managing these seasonal peaks requires much more than good organization: it requires vision, technology, and adaptability. The sudden increase in orders puts pressure on every stage of the supply chain, from receiving goods to picking and shipping. Margins for error are drastically reduced, while speed and accuracy become key factors in keeping promises made to customers.

In recent years, the market has seen increasing complexity in sales channel management: traditional distribution has been joined by increasingly dynamic e-commerce, which demands flexibility, personalization, and reduced delivery times. In this context, relying on manual or semi-automated processes is no longer sufficient. This is where automation becomes a strategic ally, capable of transforming seasonal peaks into opportunities for growth and consolidation.

Automating warehouses in the stationery sector is now a key lever for successfully tackling seasonal peaks, allowing you to increase operational capacity without having to resort to an escalation of seasonal human resources, which are often difficult to train and coordinate in a short time frame. An intelligent, well-designed system allows for advance planning, more accurate inventory management, and more efficient coordination of flows, while ensuring a smooth and reliable shopping experience for the end customer.

The main challenges include:

To successfully cope with these peaks, more and more companies in the stationery and office supplies sector are choosing to automate their logistics processes. This is precisely the path taken by OD+, a leading distributor of stationery, office, and school supplies.

ODPIÙ is one of Italy’s leading distributors of office supplies and stationery, renowned for offering innovative, high-quality products designed for retailers.

Since 2007, the ODPIÙ logistics center located in San Cipriano Po (PV) has grown to occupy an area of 25,000 m². Over the last five years, steady growth in order volumes has necessitated a complete overhaul of the logistics strategy, with the aim of optimizing multi-channel management and streamlining fulfillment operations, while reducing the overall operational impact.

To tackle this transformation, ODPIÙ turned to Errevi Automation, a system integrator and official partner of Exotec, with the task of redesigning the entire fulfillment infrastructure. The heart of the project was the adoption of a latest-generation goods-to-person solution, capable of bringing products directly to operators for picking. This has reduced manual workload and significantly increased warehouse efficiency.

The results were immediate: over 12,000 items are now stored and picked in just 900 m², thanks to high-density shelving that maximizes both vertical and horizontal space. Order management for different distribution channels is now centralized in a single integrated system, improving flexibility and speed of execution.

CASO DI STUDIO ODPIU’ | CANCELLERIA

Discover how ODPIU’ efficiently stored over 12,000 product references in a compact 900 m² (9,700 ft²) area, processing 1,000 lines per hour from three picking stations.

This project clearly demonstrates how automation is not just a technological choice, but a true strategic ally for companies that want to grow, respond flexibly to peaks in demand, and optimize the entire logistics chain. A well-designed system, such as the one implemented for ODPIÙ, is concrete proof of how innovation can translate into efficiency, speed, and competitive advantage.

The introduction of automated systems allows companies to handle high volumes of work in less time. Thanks to the ability to operate continuously, 24 hours a day, 7 days a week, robotic warehouse logistics solutions ensure consistent levels of productivity. Although the initial investment in advanced technologies may seem costly, the medium- to long-term economic benefits are significant: fewer errors, less damage, and a significant reduction in machine downtime translate into lower operating costs and a high-performance warehouse.

The introduction of automated systems allows companies to handle high volumes of work in less time. Thanks to the ability to operate continuously, 24 hours a day, 7 days a week, robotic warehouse logistics solutions ensure consistent levels of productivity. Although the initial investment in advanced technologies may seem costly, the medium- to long-term economic benefits are significant: fewer errors, less damage, and a significant reduction in machine downtime translate into lower operating costs and a high-performance warehouse.

An additional advantage is the ability to collect and analyze data more efficiently. The information obtained in this way becomes a strategic tool: it supports more accurate forecasts, improves planning, and enables more informed operational and management decisions.

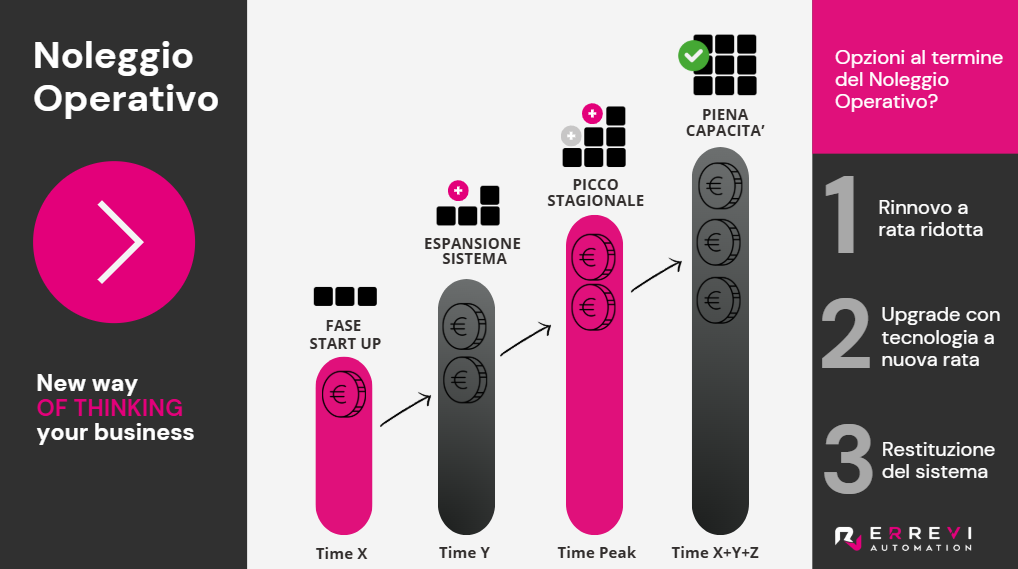

Among the most flexible solutions for effectively dealing with seasonal peaks, the operational rental of logistics robots is now an increasingly popular strategic option. We also discussed this in our article.

In the rapidly evolving world of technology, robot rental and leasing is emerging as an innovative solution that is revolutionizing the way companies in the logistics sector tackle daily challenges.

This formula allows companies to quickly integrate automated systems into their warehouses for only the period necessary, without the burden of a structural investment. In practice, it is possible to boost operational capabilities during peak seasons—such as back-to-school season in the stationery and office supplies sector—with advanced technologies, and then downsize the infrastructure once the peak is over.

An ideal solution for those seeking scalability, efficiency, and cost control, while maintaining high performance even during the most critical times of the year.

Conclusions

Warehouse automation in the stationery and office supplies sector therefore makes it possible to cope with seasonal peaks, improve logistics management, and increase flexibility with scalable solutions, such as the operational rental of logistics robots.

If you deal with office supplies and stationery and want to enhance your warehouse with permanent logistics automation solutions or tackle the peak season with the support of operational leasing, Errevi Automation is at your side to identify the solution that best suits your needs.