The expansion of the consumer goods market and the changing needs of consumers and suppliers have highlighted the fundamental role of the logistics and supply chain management in improving logistics-related processes and maintaining market competitiveness. With the increasing complexity of global supply chains and customers' expectations for timely and accurate deliveries, it is becoming more and more crucial to maximise operational efficiency and contain costs.

To optimise the supply chain, it becomes essential to accurately manage all activities of the different logistics processes, including operational cycles and information flow.

In this article:

What strategies can companies adopt to optimise logistics and supply chain management?

1. Managing the flow of goods

Managing the flow of goods is essential for a logistics and supply chain efficient. An automated warehouse is an invaluable resource for precise management of raw material supply and goods flow, ensuring a smooth process from production to dispatch. Using warehouse management software such as WCS and WMS, which is the heart of logistics, it is possible to orchestrate operations, monitor stock levels and facilitate the movement of goods within the warehouse.

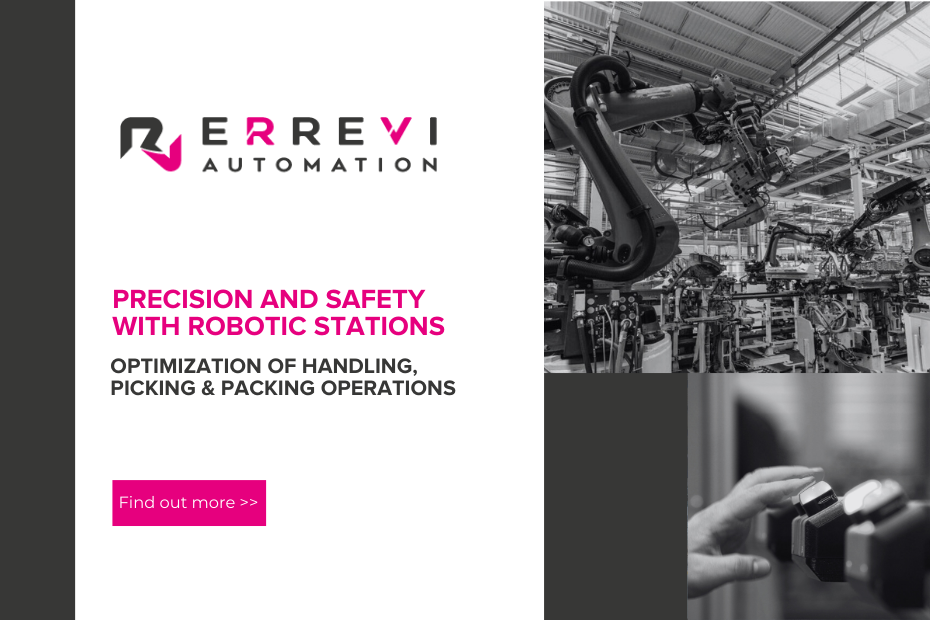

Optimised warehouse layouts and optimised goods handling processes are key to reducing picking and packing times and improving overall warehouse productivity. In addition, the automation of storage processes, with the use of precise and safe robot islands and automated picking systems, contributes to improving overall efficiency and reducing human errors in the logistics and supply chain management.

2. Optimising the Storage Phase

The choice of state-of-the-art storage system best suited to logistical needs involves consideration of the layout of the warehouse and the characteristics of the goods. It is therefore crucial to understand which goods handling solutions - such as Stacker cranes, nastri trasportatori, shuttles and other advanced technologies - can optimise performance while reducing errors and ensuring a smooth workflow.

3. Using Innovative Technologies to Manage Inventory

The adoption of innovative technologies such as theintelligenza artificiale (AI)as discussed in the article "How AI is revolutionizing warehouses' and thebig data analysis can provide companies with support to manage a number of typical operations of the logistics and supply chain. These technologies combined with automation allow real-time monitoring of goods, forecasting of demand, enabling companies to make more precise decisions in a timely manner, avoiding the risk of errors or delays. Also in this case equipping the warehouse with software is essential to identify and register products and ensure greater traceability.

4. Using order preparation software

The use of warehouse software for order management is crucial in the context of the logistics and supply chainas the accuracy and timeliness of deliveries are decisive for customer satisfaction. This phase encompasses several logistical activities, including the handling of operators within the warehouse and the picking of products from the shelves to the packaging stage.

The WMS software, as we explain in our article "WMS/WCS: what are they? What are they for?"is a valuable tool for obtaining detailed information on each order, ensuring fast deliveries and minimising errors. By managing picking systems for order preparation, the WMS software optimises operational efficiency and ensures a smooth workflow within the warehouse.

Agilog, in house- Software Engineering

he Agilog WCS from Errevi Automation, developed by our in-house team of softwarists, is the beating heart of automation solutions that allow warehouse operations to be controlled and optimised.

5. Warehouse Performance Monitoring

The constant monitoring of the performance of the logistics and supply chain and the identification of areas for improvement play a key role in maintaining high standards of efficiency over time.

In conclusion, optimising logistics automation of the warehouse and all activities revolving around the supply chain is crucial. This requires innovative technologies, reliable partners and optimisation of processes and performance.

Errevi Automation has several warehouse logistics solutions that can be adapted to their own reality with the aim of improving operational efficiency, reducing costs and maintaining an competitive advantage at increasingly complex global market.

Are you interested in maximising the benefits of logistics automation to optimise your supply chain?

Related articles from the Errevi Automation Blog

The Heart of Logistics: The Importance of Warehouse Software

In a world where speed and efficiency are crucial to success, optimisation of warehouse logistics has become critical for companies... Read more "

Optimise Warehouse Storage: Revamping Programme

The warehouse is the beating heart of many business operations. It is here that goods are received, stored and prepared for shipment. However, many... Read more "

Precision and Safety with Robotic Islands

Optimising Handling, Picking & Packing Operations In the era of Industry 4.0, where innovation is the key to success, Robotized Islands emerge as a solution... Read more "